Construction Steps

Layout Preparation /

Specification Check

Wave

Dancer Productions begins each kayak with a blueprint from Chesapeake Light

Craft. The sales team sends over to

the kayak shop any personalization or customization that the customer requests.

The boat master goes over the plans and any new specifications to ensure

that all the details work properly and that we have the entire customerís

needs met. If there are any

questions the boat master will contact the retail store first and then the

customer for further clarification.

Wave

Dancer Productions begins each kayak with a blueprint from Chesapeake Light

Craft. The sales team sends over to

the kayak shop any personalization or customization that the customer requests.

The boat master goes over the plans and any new specifications to ensure

that all the details work properly and that we have the entire customerís

needs met. If there are any

questions the boat master will contact the retail store first and then the

customer for further clarification.

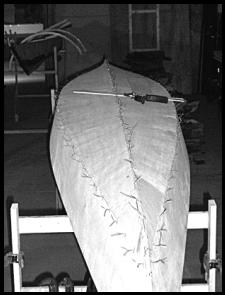

Hull Preparation

Shop personnel receive the final plans and begin to cut

out wooded blanks that form the hull and bulkheads.

These hull pieces and bulkheads are wired together to form the bottom of

the kayak. Each seam is sealed with

a wood fiber resin mixture.

The

kayak is flipped over after the hull has cured. The wires are removed and the

hull is sanded smooth to accept the fiberglass cloth that is applied to the

kayak. The cloth is filled with

clear epoxy resin, then sanded smooth.

Deck

Preparation

The

kayak is turned over to sand the interior and fit in any additional option to

personalize the kayak. Shear

clamps, which run along the inner-side of the kayak, are formed to accept the

deck material. After the deck is applied it is sanded smooth with extra care

to bring out the exceptional grain of the wood.

The deck is covered with fiberglass cloth, which is also filled with a

clear epoxy resin. The kayak

receives several sanding applications to remove any imperfections.

Painting / Varnishing

Wave

Dancer Productions take great pains to make sure that the final finish is immaculate. The hull receives a

primer layer, which is then covered with a two-part polyurethane.

The hull is highly resistant to abrasions with this coating.

The deck is coated with a marine varnish to protect the kayak from UV

rays. The deck rigging is applied

and any custom painting is completed. The

boat master inspects each kayak at every step to ensure quality. When the boat master gives his final approval the kayak is

wrapped for shipment.

Wave

Dancer Productions take great pains to make sure that the final finish is immaculate. The hull receives a

primer layer, which is then covered with a two-part polyurethane.

The hull is highly resistant to abrasions with this coating.

The deck is coated with a marine varnish to protect the kayak from UV

rays. The deck rigging is applied

and any custom painting is completed. The

boat master inspects each kayak at every step to ensure quality. When the boat master gives his final approval the kayak is

wrapped for shipment.

back

to top